Metal Anodizing: Enhancing Durability and Aesthetics

Metal Anodizing is a surface treatment process that is widely used in various industries to enhance the durability, corrosion resistance, and aesthetics of metal products. It involves creating a controlled oxide layer on the surface of the metal through an electrolytic process. This layer not only provides excellent protection against corrosion but also opens up a wide range of color options for design customization.

One of the primary

advantages of metal anodizing is its ability to significantly increase the

lifespan of metal products. The anodized layer acts as a barrier between the

metal and the surrounding environment, protecting it from factors such as

moisture, chemicals, and UV radiation. This makes anodized metals highly

resistant to corrosion, which is crucial in industries such as automotive,

aerospace, and construction, where metal components are exposed to harsh

conditions.

In addition to

corrosion resistance, Metal

Anodizing offers remarkable durability. The anodized layer is

integrated into the metal surface, making it less susceptible to wear and tear.

This makes anodized metals ideal for applications that require high-strength

and long-lasting performance, such as architectural structures, electronic

devices, and sporting equipment.

Another significant

advantage is its ability to enhance the aesthetics of metal products. The

anodized layer can be dyed in various colors, offering a vast array of design

possibilities. This makes anodizing a popular choice for industries where

visual appeal is important, such as consumer electronics, jewelry, and interior

design. The colors achieved through anodizing are not just superficial coatings

but rather penetrate the surface, resulting in vibrant and long-lasting

finishes.

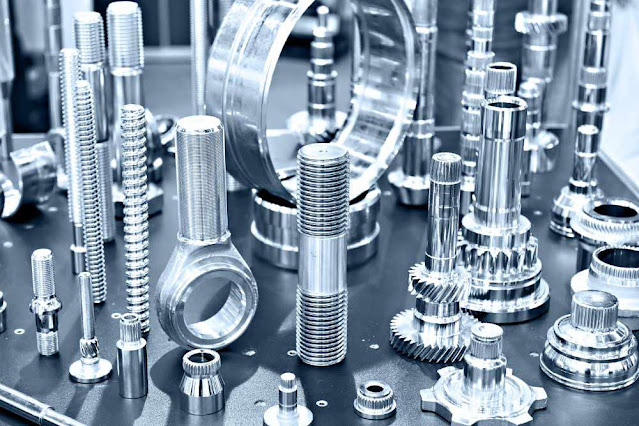

Metal

Anodizing is a versatile process that can be

applied to a wide range of metals, including aluminum, titanium, magnesium, and

even some stainless steels. Each metal has its unique anodizing

characteristics, allowing for customization based on specific requirements. For

example, hard anodizing can be used to further increase the hardness and wear

resistance of aluminum, making it suitable for applications where extreme

durability is necessary.

The process itself

involves several steps, including cleaning and preparation of the metal

surface, followed by electrolytic treatment in an acid bath. The exact

parameters of the anodizing process, such as temperature, voltage, and

duration, can be adjusted to achieve desired results, such as different

thicknesses of the anodized layer or specific colors.

Versatile surface

treatment process that offers numerous benefits to various industries. It

provides exceptional corrosion resistance, durability, and aesthetic

customization options, making it an ideal choice for a wide range of

applications. Whether it's protecting critical components in the aerospace

industry or adding a touch of elegance to consumer electronics, plays a vital

role in enhancing the performance and appearance of metal products.

Comments

Post a Comment