Polybutadiene - The Versatile Synthetic Rubber

|

| Polybutadiene |

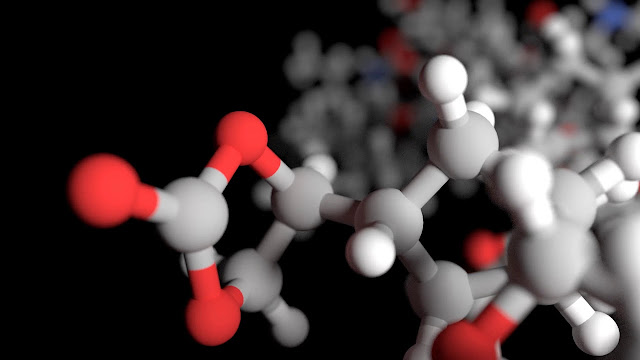

Introduction

Polybutadiene, commonly known as 'butadiene rubber' or BR, is a synthetic rubber

produced through the polymerization of the monomer 1,3-butadiene. It is a

polymer with excellent mechanical properties and finds uses across diverse

industries. In this article, we will explore the production process,

properties, applications and future prospects of polybutadiene.

Production Process

Polybutadiene is produced through a process known as 'solution polymerization'.

In this process, 1,3-butadiene monomer is dissolved in an organic solvent like

hexane or heptane in the presence of an initiator and then polymerized at high

temperatures between 60-90°C. Common initiators used are organic peroxides or

azo compounds which help in kicking off the radical polymerization reaction.

The reaction generates high molecular weight polybutadiene polymer chains

within a short span of 3-4 hours. After polymerization, the solvent is removed

through evaporation leaving behind a pale yellow to off-white colored synthetic

rubber. The properties and structure of polybutadiene can be tailored by

controlling reaction parameters like temperature, choice of solvent, type of

initiator etc.

Properties

Polybutadiene has excellent mechanical properties like flexibility, tensile

strength, abrasion and tear resistance which make it suitable for various

applications. Its properties can be broadly categorized as:

- Elasticity: High elongation at break of over 500% enables high flex

resistance and comfort.

- Toughness: Above average impact strength and tear resistance enables use in

tires and other products requiring durability.

- Temperature Resistance: It has a service temperature range of -50°C to +80°C

making it ideal for applications across climatic conditions.

- Aging Resistance: Slow rate of oxidative aging helps preserve its properties

over long term use.

- Chemistry: The double bonds in its structure allows for vulcanization and

functionalization reactions to tailor its properties.

The microstructure and hence properties of polybutadiene depend on the

cis-trans ratio of the double bonds along the polymer chain. Industrial grades

typically have a cis content between 80-98%.

Applications

Owing to its versatile mechanical properties, polybutadiene finds diverse

applications ranging from tires, footwear to adhesives and construction. Some

key applications are:

Tires - As tire tread and sidewall material, Polybutadiene

provides cushioning, wear resistance and

flex durability important for tires. Around 65% of BR produced worldwide goes

into tire manufacturing.

Footwear - Used in shoe soles and heels, it provides cushioning and flexibility

vital for comfort in footwear.

Industrial Rubber Products - Hoses, belts, gaskets, seals utilize its ability

to withstand vibration and flex fatigue over extended use.

Adhesives - Its adhering properties make it useful in contact adhesives,

sealants and emulsion adhesives.

Sports Goods - In articles like bowling balls, sports mats etc where resiliency

and toughness are key.

Modification and Future

Traditional polybutadiene can be further modified to introduce improved

properties. Some notable modified variants are:

- High Cis Polybutadiene - Increased cis content above 95% provides enhanced

strength and hardness for specialized tire compounds.

- Butyl Rubber - Copolymerization with 15-45% isobutylene introduces improved

air retention for innerliners in tubeless tires.

- Acrylonitrile Butadiene Rubber (NBR) - Copolymer of acrylonitrile and

butadiene with oil and solvent resistance and strong adhesion.

With the increased focus on sustainability, new generation polybutadienes synthesized

from plant based bio-butadiene are also being researched which can reduce

fossil resource dependency. Continuous product innovation focusing on

reinforcement of properties, development of specialty grades and bio-based

variants will pave the way for polybutadiene rubber in the future.

Polybutadiene has established itself

as a dependable synthetic rubber owing to its ability to deliver performance at

economic costs. Versatile mechanical properties along with easy processability

have enabled it to effectively replace natural rubber in many applications.

Continuous efforts to further enhance its strengths and develop new specialty

variants will ensure it remains relevant in the rubber industry going forward.

Get

more insights, On Polybutadiene

Check

more trending articles related to this topic: Stem Cells

Market

Comments

Post a Comment